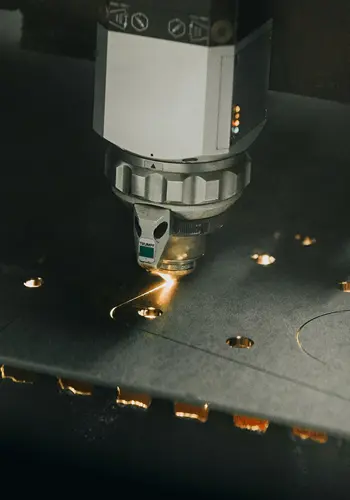

Multi-operation machining

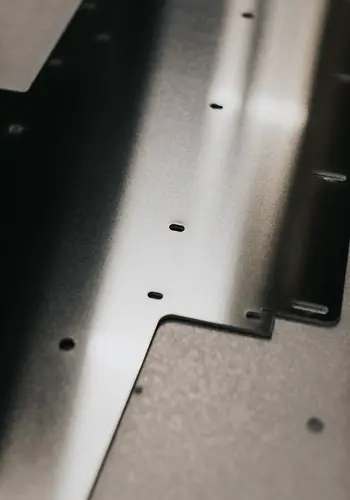

Our multi-operation machining creates the opportunity to carry out several further processing steps at the same time, significantly reducing the total machining time. The lower energy consumption and minimal material waste also contribute to more sustainable fabrication. The key here is developing special solutions for parts that must be machined with exact precision in order to be delivered directly into our customers' manufacturing processes.

At Rotage, our multi-operation machines are controlled by skilled operators who manage the process and pick parts. A fine processing takes place down to 0.01 mm of the cut blank. Exact tolerances are supplied wholly in accordance with the required specification. Multi-operation machines also enable screw threading and countersinks in thicker material that cannot be run in a punch.

We produce a turnkey solution based on your requirements!

Need help optimizing your manufacturing?

Don’t hesitate to get in touch to discuss your questions and requirements. Our production engineers will gladly share their knowledge and experience to find a turnkey solution that will streamline and improve your production.